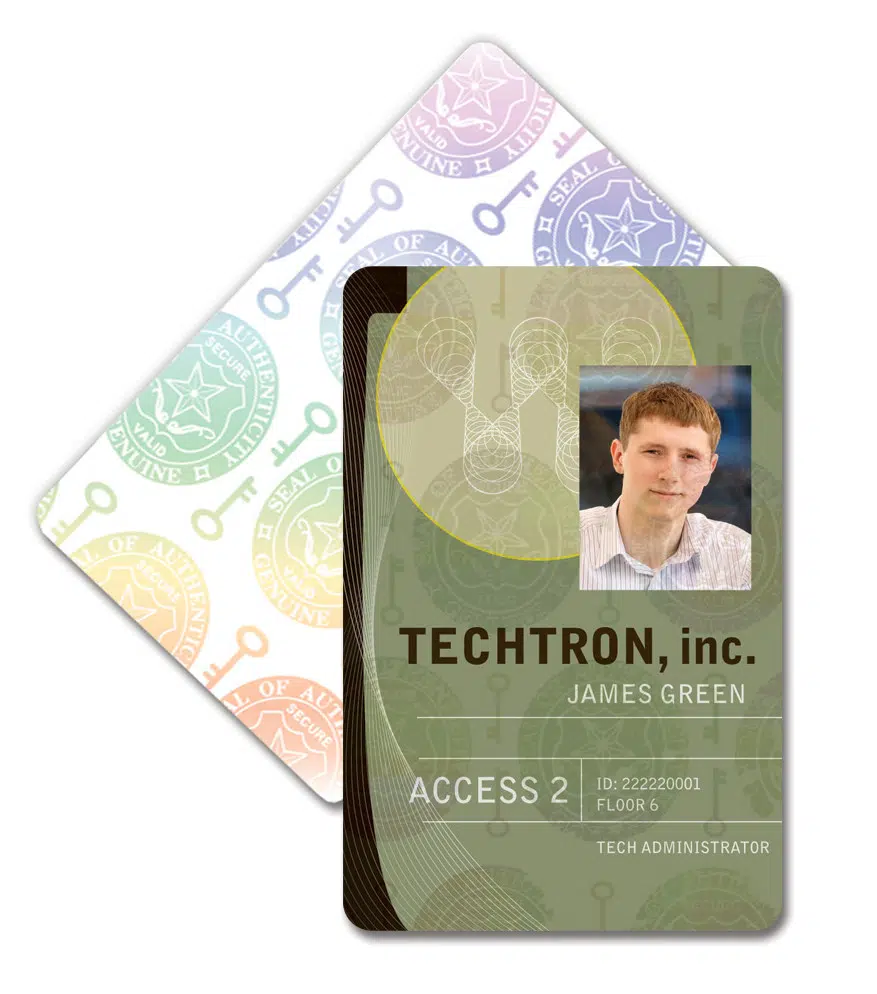

Offset Printing

The highest quality of print is what is known as offset printing. Offset printing can only be a possibility when the PVC cards are being printed where they are manufactured. The reason for this is because it’s only feasible for large quantities and when all of the data is available prior to printing. This method cannot be used on an individual basis for on-demand printing.

On-Demand Printing Technologies

If you’re wanting to print cards individually or in small batches, there are two technologies available.

- Direct-to-Card (DTC) – This is where the ink panels are applied directly to the surface of the ID card.

- Thermal Retransfer – This is where the ink panels are first adhered to a clear film, in which case the film is then adhered to the ID card.

DTC is the least expensive of the 3 options and can be a great fit for certain applications, although is does have its disadvantages. Because if the direct printing, the color rendering is not quite as sharp and has limitations on where your content can be applied to the card. This method does not allow for edge-to-edge printing so a full color design would not work well. In that instance, the card would have a white line around the edge of the card where ink could not be applied.

Retransfer printing, on the other hand, can be printed from edge-to-edge and displays a higher vibrancy of color and definition. This method is also a much better choice for cards that do not have an even surface such as PROX or RFID cards. Those types of cards have raised areas where a chip is embedded to store information.

If you would like more information about which technology would be right for you, give us a call! We would be delighted to help you find the perfect printing solutions! Call (866) 610-4308