Why Dye Sublimation?

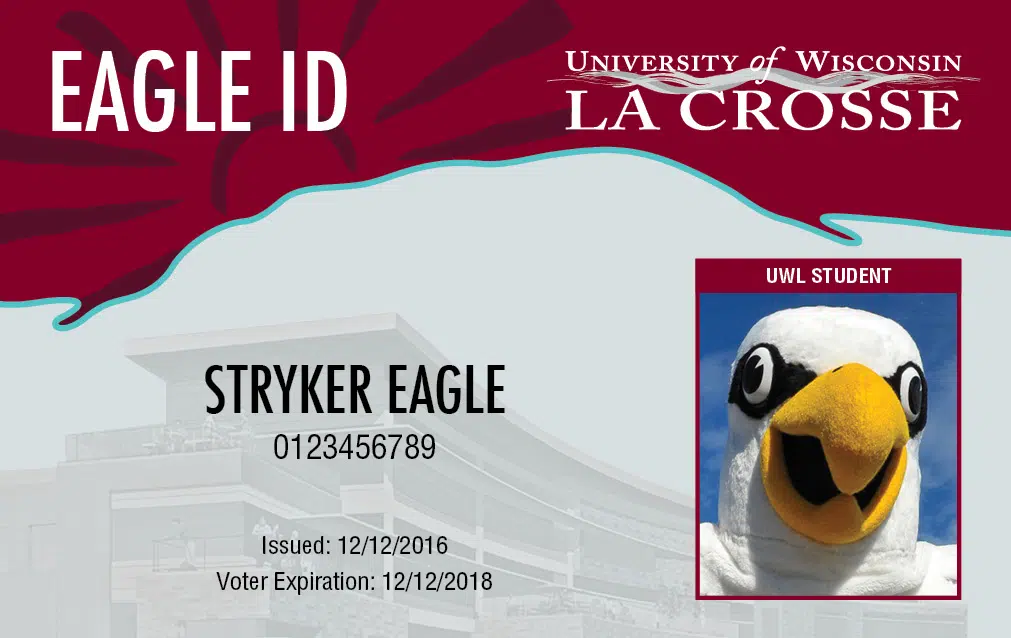

Dye sublimation printing, also known as “direct-to-card” printing, differs from that of a inkjet printer in that it does not lay down the ink as individual dots. Instead, it imprints the image into the plastic using heat. Inkjet printing is not adequate for printing on plastics because the individual dots can be seen at close range which significantly reduces image quality and clarity.

How it Works

If you were to look on the inside of a dye sublimation printer you would see a large roll of film. This film contains panels with the four basic colors used in printing. (Yellow, Magenta, Cyan, Black)

During the printing process, as it passes over the film, the printer’s printhead will heat up. This causes the dye to vaporize and adhere to the plastic ID card. The vaporized ink actually permeates the glossy surface of the plastic before it returns to a solid state.

The primary differentiating factor between dye sublimation and other types of printing is the heat. It’s the heat from the printhead that transfers the image from the ribbon to the card’s surface. The advantages of this type of printing, include:

- Brilliant colors. (Due to the bonding of the dye to the card surface)

- Images are permanent.

- Images tones that are equivalent to standard photographs.

There are two types of ID cards printers that use the dye sublimation method (Direct-to-card and Re-trasnfer). Both produce very high quality prints, however the direct-to-card printers do not print well on cards with uneven surfaces such as clamshell cards. In that case a re-transer printer would be the best option.